Project new

the biobased packaging revolution

Packaging plays a crucial role in safely transporting food and beverages from producers to consumers, ensuring their preservation and safety. However, its production and disposal is posing a serious threat to the environment. Packaging is predominantly made from fossil-fuel-based plastics, it requires substantial amounts of virgin materials and it is poorly recycled. In 2021, 44% of the world’s total plastic production was used for packaging with a recycling rate of 26.9%. With fossil resources becoming less available each day, bio-based packaging materials have been identified as potential solutions to address waste management issues, in line with circular economy principles.

That's why researchers, packaging manufacturers, NGOs, and SMEs have joined forces in the PRESERVE project to develop innovative bio-based packaging solutions, with the goal of bringing new, viable circular alternatives to the market. PRESERVE is a European research initiative aimed at improving the recyclability of food packaging through innovative biopolymer synthesis. The project focuses on advancing bio-based packaging by enhancing bio-coatings for better recyclability. Additionally, PRESERVE ensures that these materials can be upcycled into new containers and textiles for non-food uses.

Bioplastics recycling is the key

While Europe depends heavily on fossil-derived plastics and consumes in the range of 50 million tonnes of plastic per year, only 32% of the resulting waste is currently recycled. Given that packaging consumes more than 40% of all plastic produced each year, improving its circularity from origin to subsequent life cycles is more than urgent.

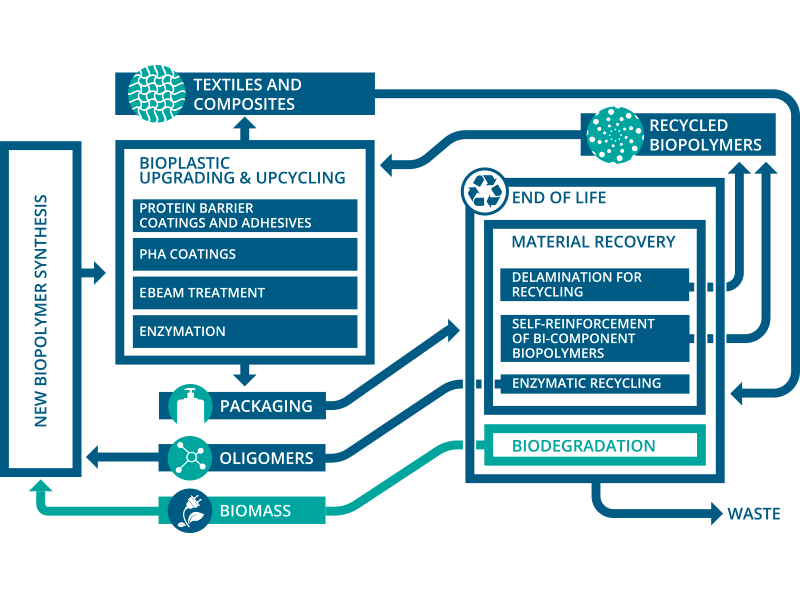

Our upcycling strategies to boost packaging performance in the first and subsequent life cycles of the materials comprise several steps:

A circular approach

for bioplastic consumer products

PRESERVE main results

PRESERVE envisions a transformative approach to address pressing challenges in reducing plastic waste, introducing groundbreaking innovations that aim to redefine how we design food packaging. By tackling key bottlenecks in recycling and upcycling, this initiative targets both traditional and modern obstacles, focusing on solutions that are adaptable, sustainable, and scalable. Discover more about the results we obtained.

At the moment, traditional coatings are made with fossil fuel based polyethylene or other solutions such as PLA, acrylic or waxes coatings which hinders the recyclability of the products. The PHA coatings developed in this project will serve as a sustainable alternative to the coatings that currently surface most paper and board products since they will be bio-based reducing the consumption of polymers from fossil sources.

Textile industry has issues regarding microfibre shedding during use phase and washing. This problem is emphasized when fabrics are based on recycled materials. Finish coating treatments assist to mitigate this problem. The result consists of a biobased formulation which reduced the number of microfibers released from an (r-)PET or (r-)PLA fabric and is not harmful to organisms in the environment. The developed product is a new alternative on the market and anticipates current issues in the textile sector regarding microfibre release.

Currently, numerous packaging materials are composed of several components to achieve the desired shelf-life properties. These co-extruded products, such as PA/PE or PET/PE films which are much used for example for modified atmosphere packaging (MAP) or to provide puncture resistance of vacuum food packaging, are currently recycled as blends with inferior mechanical properties even after compatibilization.

Within PRESERVE, the goal is to produce bio-based microfibrillar reinforced materials of PE/PET and PE/PA coming from recycling streams. As a result, intimate blending enables the creation of materials with customized properties that outperform existing homopolymers. The microfibrillar reinforcement is an interesting approach for the upcycling of mixed polymer waste, with tailored applications.

Within PRESERVE, a new method for the elimination of bio-based coatings has been developed. With the use of an enzymatic soap, whey-based coating from PE, PET, cardboard and PLA and also from multilayer has been removed. A complete delamination process has been developed in four steps: shreedding, washing, separation, and pelletizing. This method will facilitate the separation of multilayer packaging containing the PRESERVE protein coating, thereby enabling the recycling and recovery of biobased materials in an efficient and straightforward manner. Furthermore, the method is readily replicable.

In PRESERVE, we have developed a demonstrator that proves that industrial recycling of discarded bio-based plastic packaging (PLA) can lead to a new, attractive and reproduceable non-food product application that may be of value to the companies that produce and sell the initial products with their packaging and communicate their circular ambitions. We also look at reducing the release of microplastics with bio-based coatings.

These methods allow for the closing the loop of material use, especially that of bio-based plastics, in order to reduce the CO2 footprint. In this way, recycled materials can be reused in ways that will also allow not only the reduction of plastic waste, but also the purposeful reuse of recycled materials. For companies putting plastic packaging in the market, it would be a great opportunity to reuse their packaging for marketing purposes.

Metallization of packaging layers contributes to enhance barrier properties, resulting in an almost impermeable layer. The downside is that upon application on polymer films, it interferes with the recycling of said polymer films resulting in colour distortion. The combination of the protein coating and the metallization would simplify the delamination process and would show ultra-high oxygen barrier properties.

This innovation addresses a critical challenge in polymer recycling by ensuring that metallization applied to a protein coating does not interfere with recycling processes.When the protein coating is enzymatically degraded for delamination, the metallization ends up in the wash water. Consequently, the metallization will not affect the polymer recycling. Metallizing protein-based coatings usually bears the risk of damages occurring in the protein layer in form of cracks and holes due to the process of metallization in the high vacuum chamber. Despite previous concerns, no visible nor measurable defects in the WPI-layer on the substrate could be detected and excellent barrier properties could be achieved. Investigated substrates were films of PLA, PET, and PE.

Eco-design of packaging involves a concept where the materials used have less impact on the environment in each stage of the packaging life. This means using bio-based raw materials, biodegradable (if it is possible) or recyclable Secondary Raw Materials (SRM) and less microplastic release. With this method, more eco-friendly packaging solutions will be available which actually have a low environmental impact, less microplastic release and an end-life closing the loop (SRM or biodegradable) with an independence from fossil-based raw materials.

For the recyclable solutions, an application for these SRMs will also be found. Packaging concepts and the use of SRM must usually be adapted. The pollution on the planet is increasing every day and this eco-packaging concept will help to reduce the CO2 footprint, microplastic release and the reuse of the resources. One of the risks related to this solution is the discontinuous availability of resources, quality of SRM and possible pollution/contamination in collected bio-based plastic.

Upcycling food and drink packaging: a policy overview

Throughout the implementation of the PRESERVE project, the evolution of policy on food and drink packaging has been closely monitored.

European Bioplastics regularly reported on the impacts, boundaries, and the development of policy frameworks and informed the project consortium partners on the possible effects of (new) legislation on the project R&D´s activities and objectives.

Since the project implementation, the Commission has published the Communication for a Policy Framework for bio-based, biodegradable and compostable plastics, and the proposal for a Packaging and Packaging Waste Regulation has been adopted.

Our trans-disciplinary team combines all the relevant skills and organisations needed to address the full extent of the challenge of developing and validating innovative sustainable bio-based packaging and end of life valorisation solutions.

The participation of leading industry players demonstrates the soundness of the concept and will maximize the consortium’s ability to transfer project results into market-ready solutions. PRESERVE will transfer know-how across its value chain, from 7 technology institutes and academia to industry participants, including:

- 4 polymers and bio-based raw materials providers

- 4 plastic/packaging converters

- 3 end-users/packers

- 5 upcyclers, providers of technological solutions, H&S, and environmental assessment experts

- 2 innovation/dissemination specialists

Additional stakeholders will be involved for technical, policy, and business insights, particularly in sectors using packaging and other potential adopters of upcycled secondary raw materials and retailers.

The demonstrator and other potential project applications

Bio-based packaging for food and drinks (primary upcycled bioplastics)

- To-go pocket tray

- Snack flowpack

- Dairy pouch

- Beverage brick

- Molded fibre cup

SRM upcycling into cosmetic packaging, textiles and composites

- Injected cosmetic jars

- Blow-molded cosmetic bottles

- Non-woven shopping bags

- Carrier and display boxes