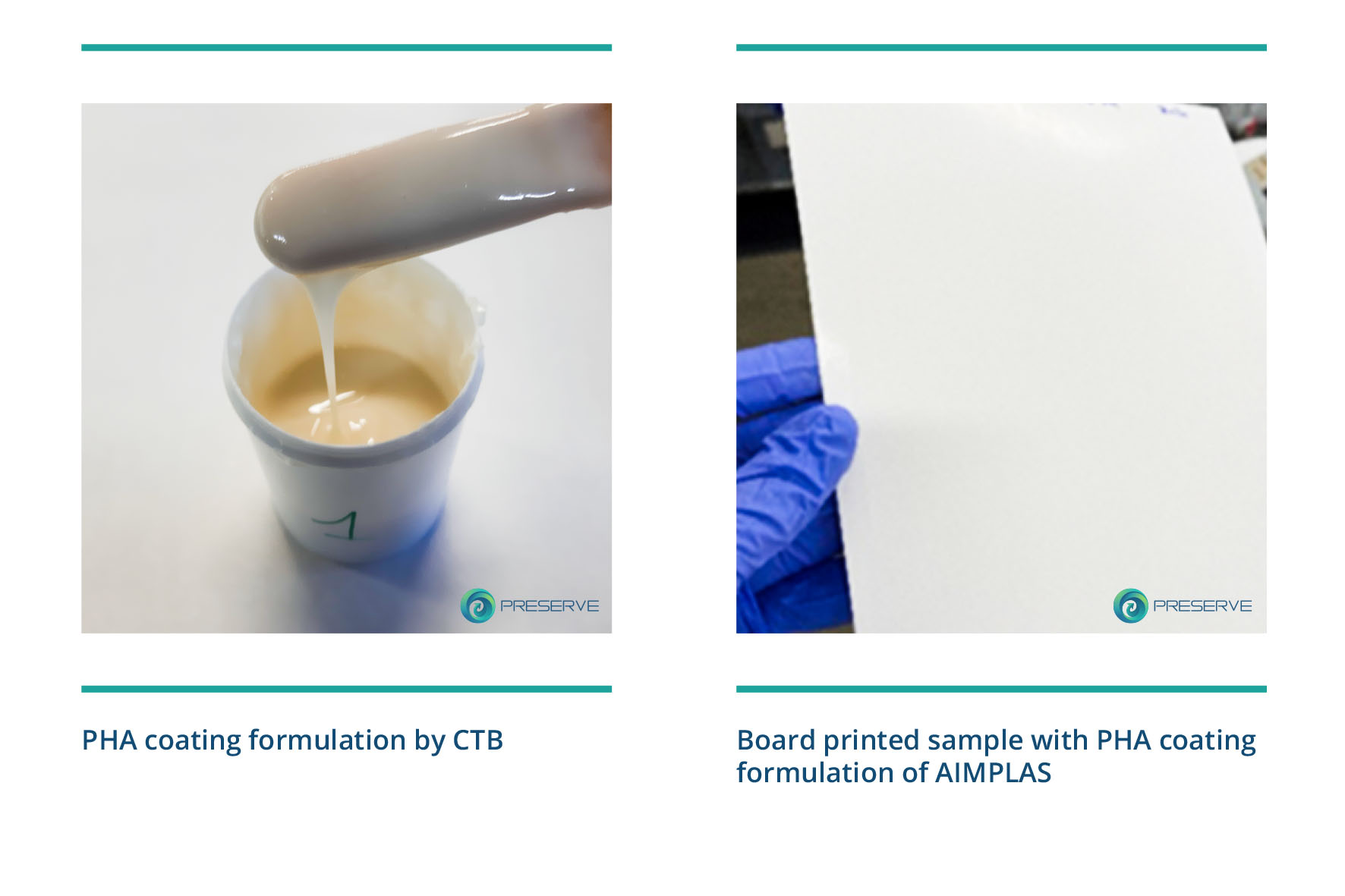

The objective of Deliverable 3.3. is the development of PHA coating formulations to improve the water vapour barrier properties of bio-based packaging, mainly in fiber-based packaging. Different PHA coating formulations have been performed (solvent-based, water-based and 100% solids) based on middle-chain PHAs obtained by BIOPOLIS and commercial ones. Excellent water resistance values have been obtained for the water-based and the 100% solids PHA coating formulation.

The use of bio-based materials has shown a strong growth due to recent trends in the consumer market moving toward greener packaging in order to reduce the waste and preserve fossil resources. Bioplastics have shown a huge potential to replace petroleum-based plastic in a wide range of industries since they have several advantages in terms of biodegradability, low carbon footprint, energy efficiency, versatility and societal acceptance.

Nevertheless, in order to be considered as a real alternative to conventional plastics, these bio-based materials need to fulfil some technical expectations (barrier and mechanical properties). The main objective of the PRESERVE project is to substitute fossil fuels derived plastics used in food and drink packaging with bio-based ones. To fulfil that, it is necessary to enhance bio-based packaging in terms of properties. This deliverable D3.3. describes the development of polyhydroxyalkanoates (PHA) coatings formulations in order to improve the water vapour barrier properties of bio-based packaging. PHA is a highly sought material due to its exceptional biodegradability and good film-forming properties and they have been shown to be good candidates to provide water-vapour barrier properties when they have been manufactured by extrusion processes. The objective of this deliverable is to use this material in the formulation of coatings, where its application continues to be a challenge.

The confidential report provides detailed information on the results of different PHA coating formulations (solvent-based, water-based and 100% solids) obtained by AIMPLAS and CENTEXBEL that will be used to develop new packaging solutions. Excellent water resistance values have been obtained around 1 g/m2 (Cobb120), equal to commercial wax-based solutions and work is being performed to optimise the water vapour barrier properties through the addition of crosslinkers, nucleating agents and nanofillers and also making blends with other biopolymers.

This is a confidential deliverable, as such the full deliverable is not available to the public.